Whether for cars, refrigerators or soldering systems - the information provided by manufacturers regarding consumption is often opaque due to the special "in-house test conditions". SMT Wertheim has undergone external and independent testing - at TÜV Süd.

Heating up the system is the most energy-intensive part of the process. Depending on the required profile and the individual product requirements, energy consumption values of 50kWh - 80kWh can occur in the heating phase - regardless of the manufacturer and type of system.

Once the reflow system is ready for operation, the consumption values vary greatly.

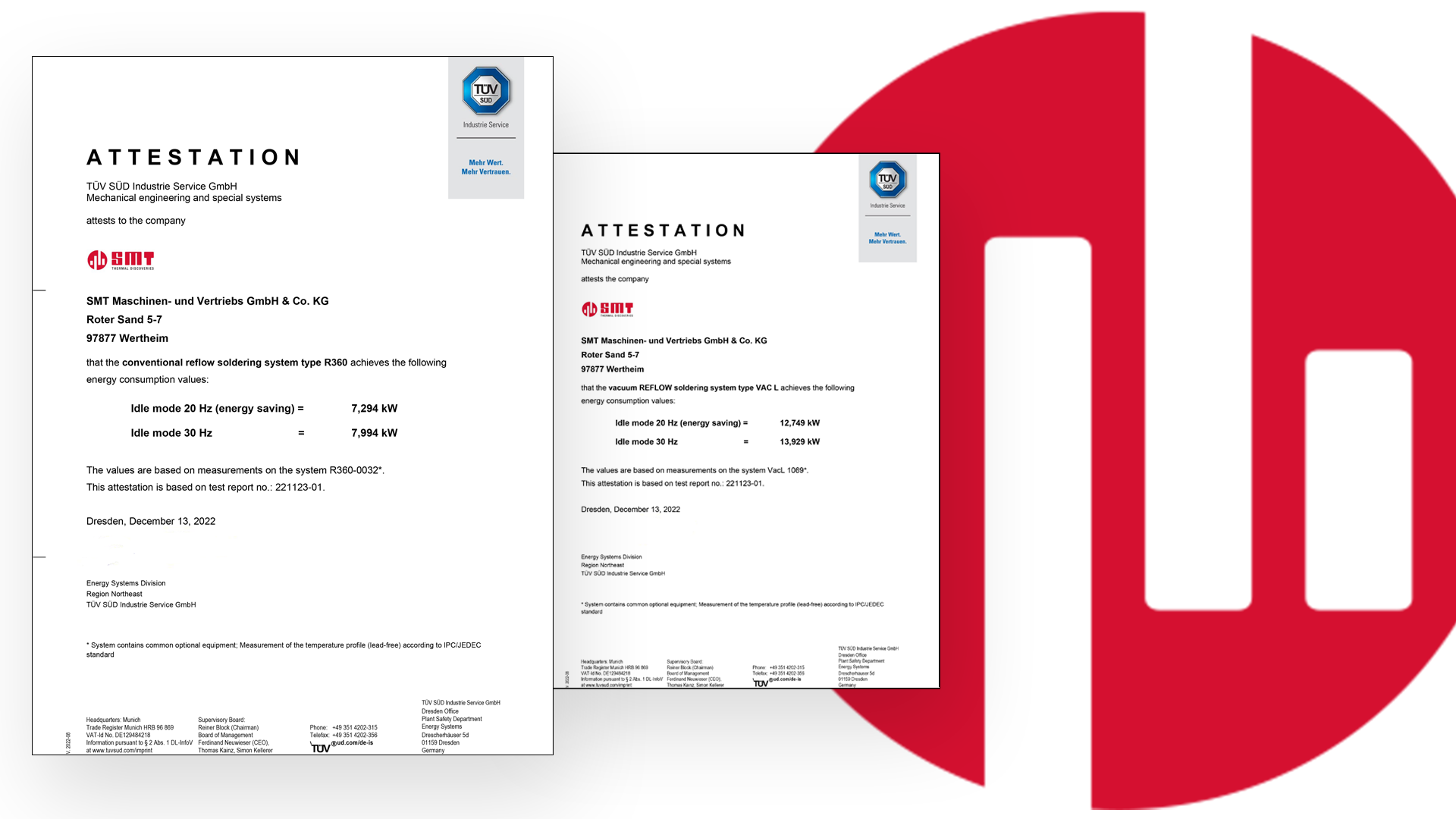

SMT Wertheim is proud to be able to achieve absolute top values in independent consumption measurements by TÜV Süd. A reflow system of the type R360 with a heating zone length of 3.6m and a vacuum reflow system of the type Vac L were tested.

In order to maintain consistently low energy consumption values, it is essential to avoid temperature changes. Thanks to SMT's award-winning Profiling Plus solution, there is no need for this.

Machines - more efficient than ever before

Process gas cleaning / flux management

Productronica Innovation Award for SMt Wertheim

Watch Global SMT & Packaging's Panel Discussion "Sustainable manufacturing and how to reduce energy and your carbon footprint" with SMT Wertheim's CEO Dr. Christian Ulzhöfer at SMTconnect 2023

Developments - Innovations & Events with SMT Wertheim