As the world’s first Calib_O2 by SMT Thermal Discoveries offers the possibility to further optimize the residual oxygen measurement during the soldering process on site.

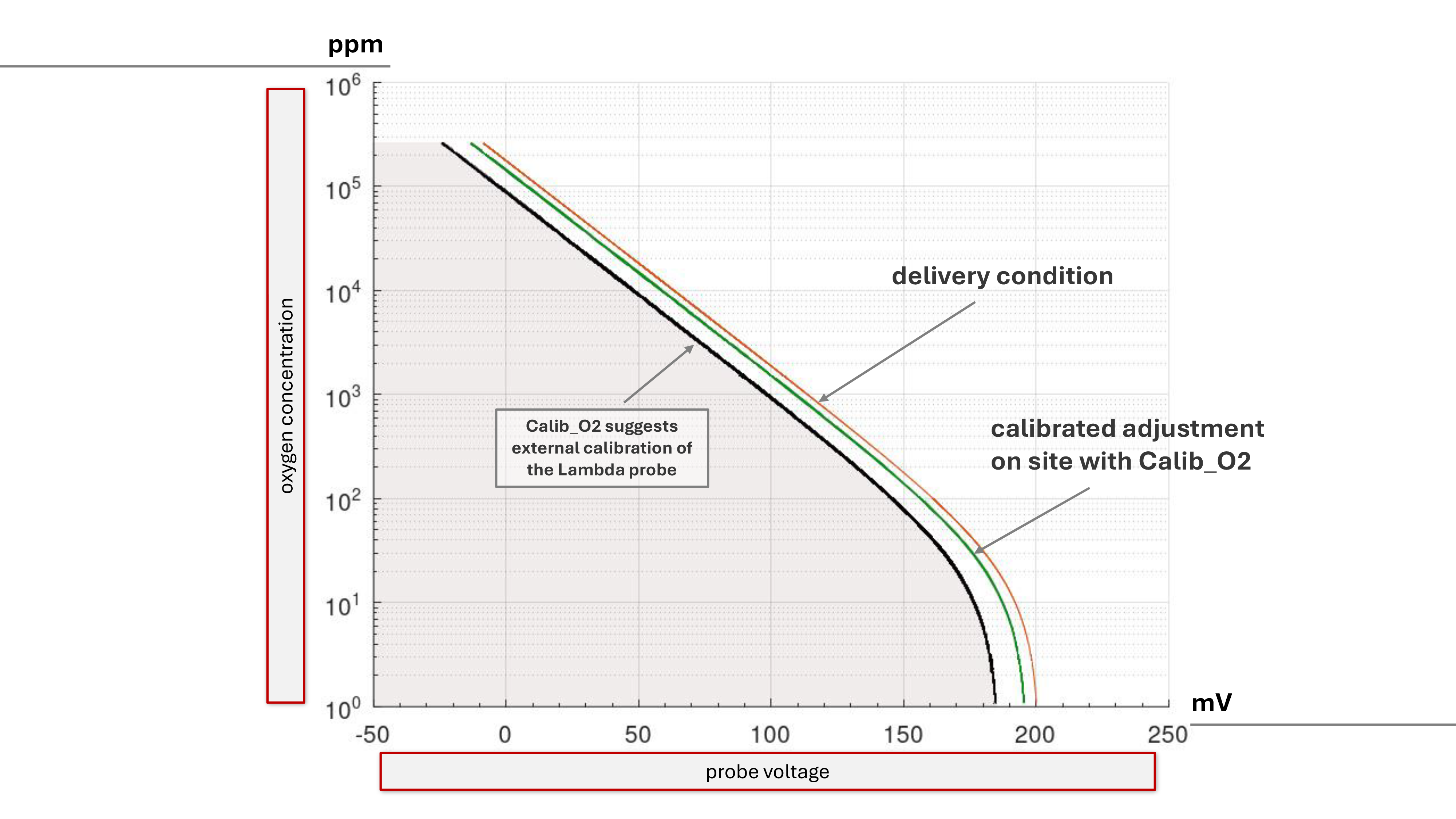

The “Calib_O2” function calibrates the residual oxygen measurement value of the lambda probe (O₂ value) to an accuracy of better than 2% and does so in the user’s on-site system. At the same time, the calibration software determines the drift of the measured O₂ values compared to the delivery state and, if necessary, displays the suggestion for an external calibration of the lambda sensor.

With every use of “Calib_O2”, the user has the certainty that the measuring device is in the best possible tolerance and the process capability is optimized to the maximum.

The solution uses a newly developed algorithm to determine reference values, which are used to recalibrate the lambda sensor. The delivery status of the lambda sensor is compared and monitored with each application. The user receives a residual oxygen measuring device that is calibrated with better than 2% accuracy and thus the highest level of process reliability. If an external calibration is necessary, it will be indicated by the “Calib-O2” application.<o:p></o:p>

The application process takes approximately 10 minutes. The software determines all reference points and the lambda sensor is recalibrated. The procedure can be repeated as often as required, e.g. as part of bi-monthly maintenance.

The solution can be installed on all systems with Thermal Tools software.

Unsere Anlagen auf dem Prüfstand - beim TÜV Süd

Prozessgasreinigung - Fluxmanagement

Profiling Plus erhält Productronica Innovation Award

Developments - Innovations & Events with SMT Wertheim